Nous joindre

Améliorer la luminosité de la pulpe et réduire le dioxyde de chlore (ClO2), les goulots d’étranglement de production et la réversion grâce aux technologies post-eau de Javel Vybrant®

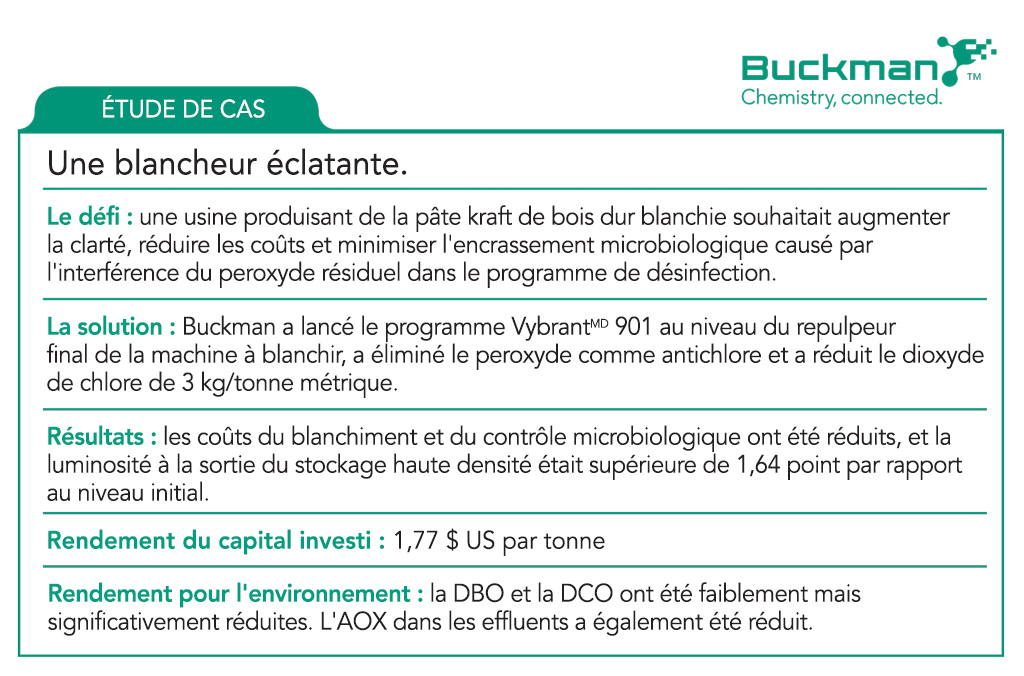

La réversion et le jaune peuvent réduire la luminosité et l’attrait de votre pulpe. Mais maintenant, il y a la série Vybrant 900, de nouvelles technologies enzymatiques post-eau de Javel de Buckman. Ils utilisent des enzymes spécialement sélectionnées pour retirer en toute sécurité les chromophores de la pulpe blanchie. Avec les produits de la série Vybrant 900, vous pouvez atteindre vos objectifs de luminosité et réduire significativement la réversion tout en réduisant, voire en éliminant, le coût des blanchisseurs optiques et autres produits blanchissants – vous faisant économiser de l’argent.

Économisez de l’argent.

Vous pouvez ainsi réduire les coûts des produits chimiques de blanchiment et réduire l’utilisation de colorants et d’agents éclaircissants optiques sur la machine à papier.

Améliorer la production.

Avec Vybrant, les goulots d’étranglement de production dus aux limites de dioxyde de chlore peuvent être révolus.

Réduisez l’AOX et la cause de la maladie.

Avec Vybrant, moins de dioxyde de chlore signifie que vous pouvez réduire les halogénures organiques adsorbables (AOX) et la demande chimique en oxygène (COD) dans les effluents.

Rendez-le sans danger alimentaire.

La série Vybrant 900 de produits post-eau de Javel est autorisée selon la réglementation de la FDA américaine (21 CFR § 176.170 et 176.180) et figure dans les recommandations BfR (XXXVI).

Technologie enzymatique post-javel de Vybrant

Réduisez la consommation de dioxyde de chlore, les goulets d’étranglement et la réversion de la luminosité avec le Vybrant.

EN SAVOIR PLUS